Subscribe to the Newsletter...

Sign Up To NewsletterAbout Trio...

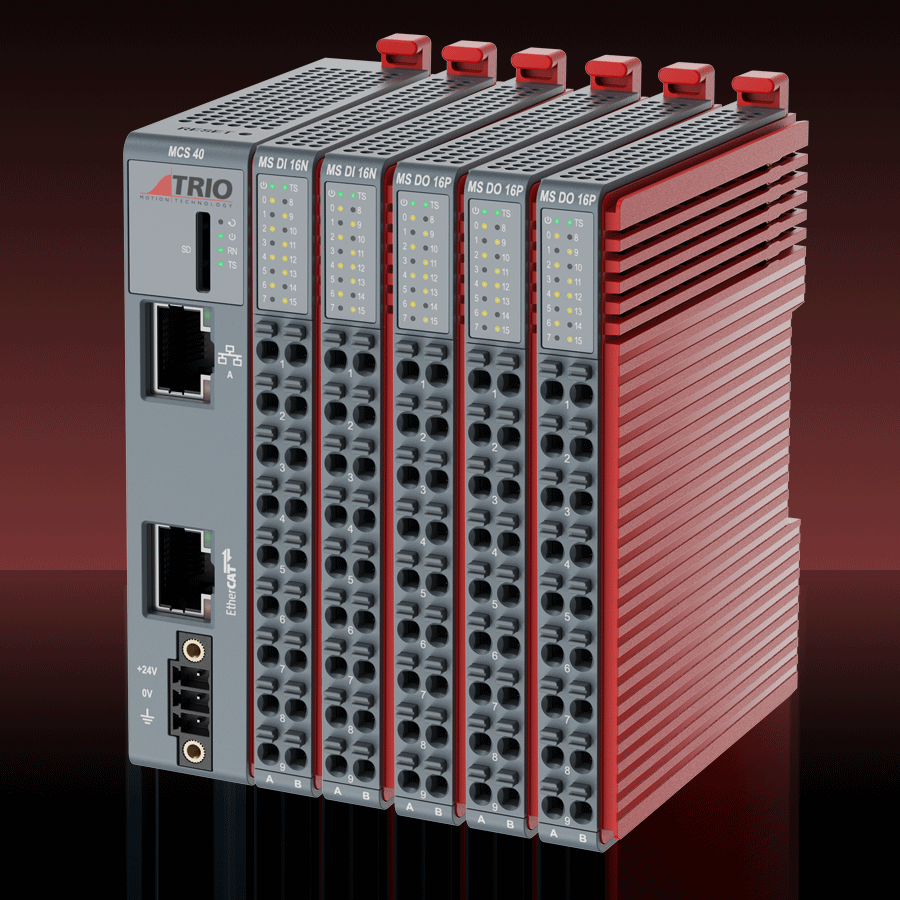

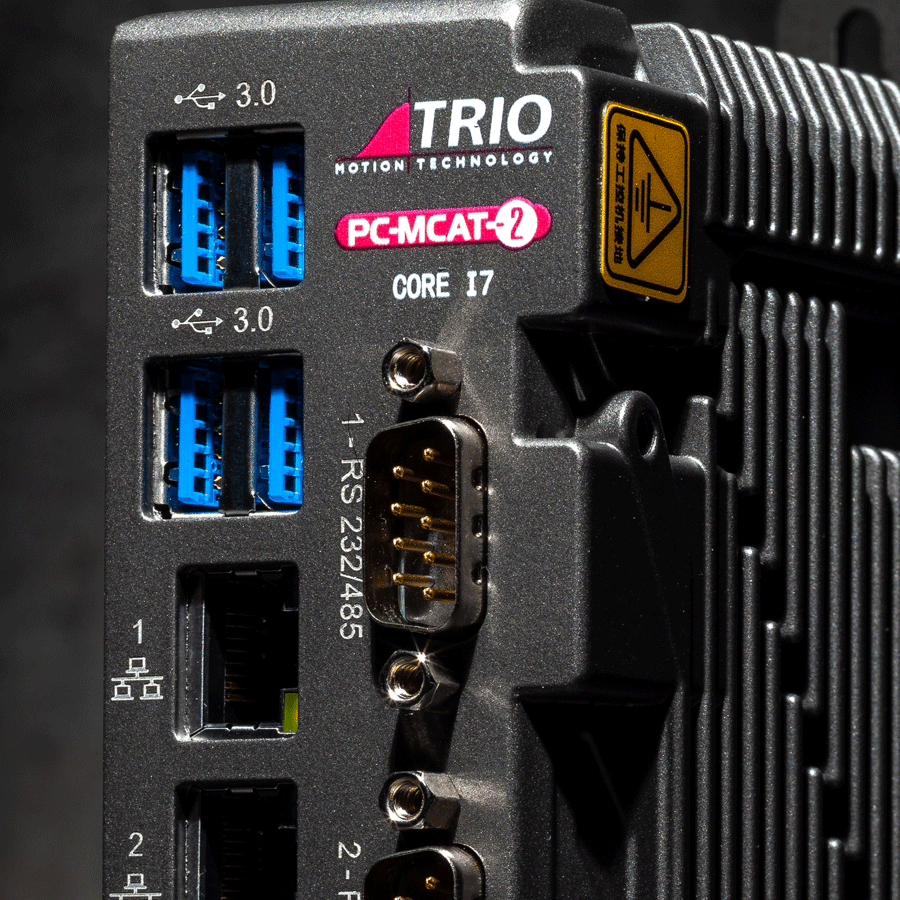

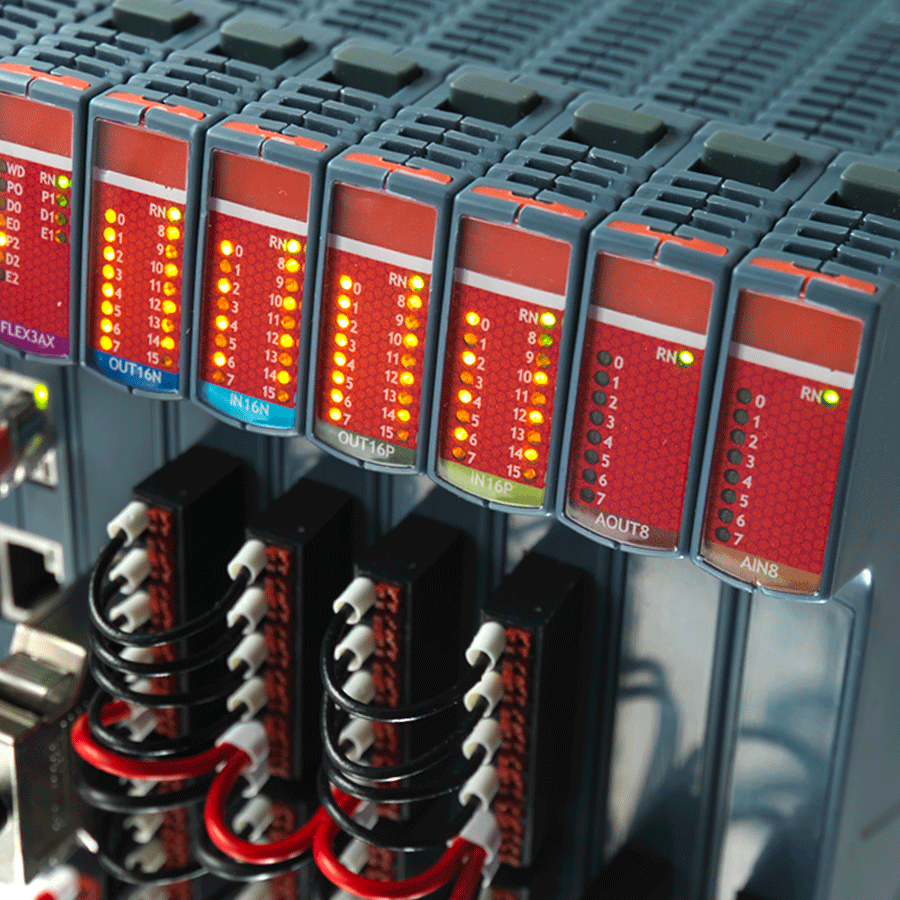

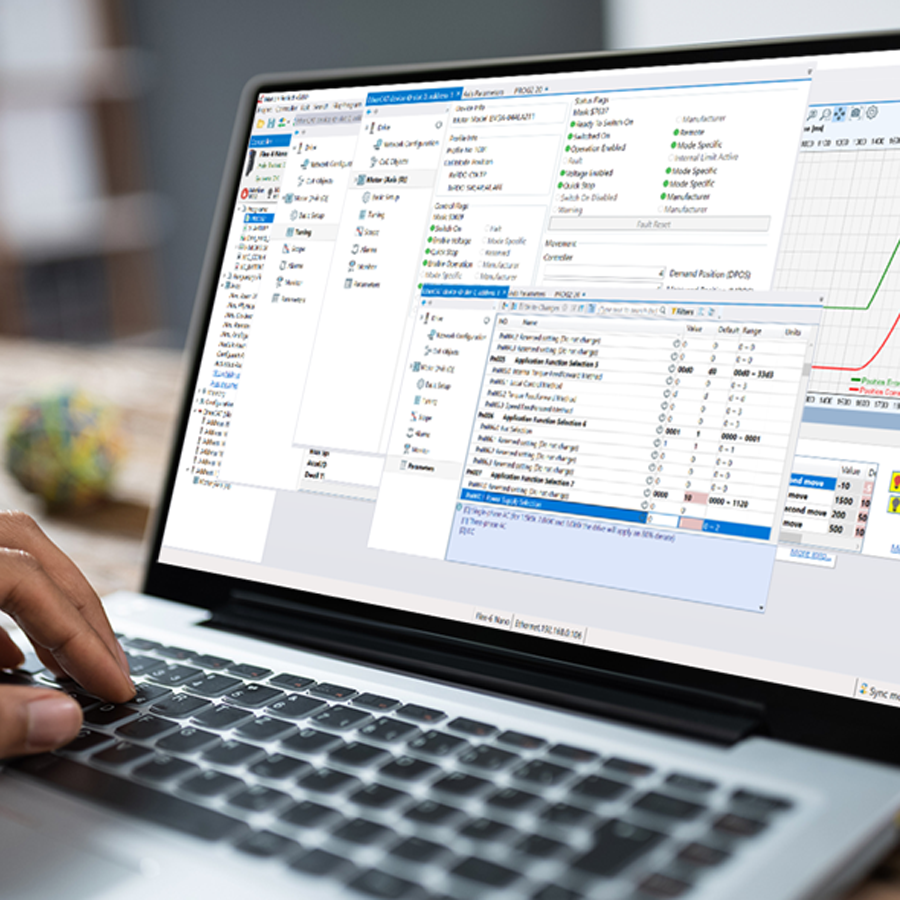

Trio Motion Technology was founded in 1987 as a manufacturer of motion controllers. Today the range, branded Motion Coordinators,can control up to 128 axes of servo, stepper and piezo motors as well as hydraulic systems. Trio’s expertise of motion programming is based within its' Motion-iX technology. Launch of the new servo drive and motor package now develops Trio’s offering into a motion solution in addition to providing motion controllers for automation vendors and system integrators.

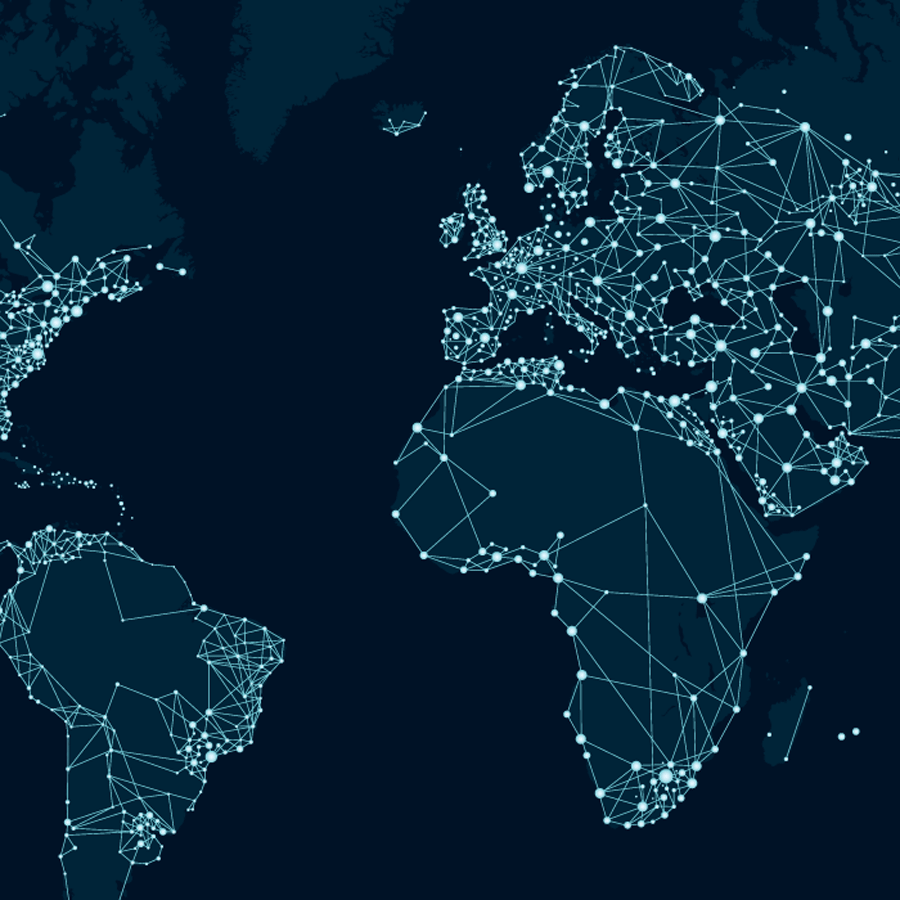

The company headquarters is based in Tewkesbury, Gloucestershire, which also comprises its primary research and development hub. Additional R&D facilities are located in Italy, Bulgaria,and China. Application development teams are located in the UK, USA, Italy, India and China, and a global sales network comprises over 100 partners.

In 2017 Trio was acquired by the Estun Group, which is supporting Trio in its growth with assistance through shared facilities and R&D as well as financial backing. Trio has exceeded 15% growth year on year since the acquisition. In addition to the primary global markets, a significant proportion of Trio’s business is in China where the company’s motion control capability has enabled Estun to become a major player in the China automation market. Despite the presence of the Estun brand, motion control products in China carry Trio branding.

What Others Say About Trio

This was the first time I've used Trio and compared to the other motion controllers I've used, the breadth and detail of the software and the sleek, compact hardware are impressive. And all at a great price. Thanks for the support!

Thanks again for a fantastic training session. Once I have had some time to go through the software, if I may I will get in touch regarding the most appropriate hardware for the film application.

First and foremost, hats off to the team for the demo of the RPS with the pallet template . Dennis and Jason were both raving about the Trio front end and control capabilities and what a nice looking, clean mechanical and controls package we had to present.

For those of us who have spent our lives in motion control it is easy to forget that many new customers have no previous experience of motion control. To them it is just a word. However when all is said and done the Trio is probably the most powerful I have ever had my hands on.

When a customer asks me, why use Trio? I say, if you have you wouldn’t be asking me.

We are all very impressed with your response and implementation, and it suits our application perfectly.

After looking for work-arounds for the last two days, it only took 30 minutes to understand, implement and test the two functions which certainly tells me you have designed a very intelligent and intuitive system.

Tony, Your help and timely response was crucial to getting this job done, I wanted to let you know how much I appreciate it.

This is my first real application with Trio, and although it wasn't a very complicated job I needed it to go quickly to meet the delivery.

Everything about this controller was perfect for the application and the software was very simple to work with. Trio will get my vote for future applications where applicable.

Thanks again, great first experience and excellent customer support.

The machine ran 460 labels/minute, with a speed of app. 58 m/mins, easily within the precision-requirements of the customer - This is actually 50% faster then needed!

The performance of MC405 it's incredible, we have increased the machine speed and the control of the drive has more accuracy compared to the Euro205.

Trio ROCKS!

I have to hand it to you guys... the products are great, robust, scalable, flexible, cost effective and with great form factors!

Please pass it along to the folks at the home office and if you have someone on the fence and need a customer for them to call, please give them my info.

Thanks again for the great products and outstanding support.

Two new P730 modules were sent immediately by Express Delivery Service after my distributor made a call, was delivered to him the very same day. After that, he kindly sent them by a bus from Slovenia to Belgrade, Serbia.

My delivery guy took them and brought them to the workshop in less than an hour. So, the modules were delivered in 36 hours after I made a request! They are now at the machine, working perfectly! I thank all of you guys so much for what I call the real support!

Thank you for having us at the classes last week. Training is very important for us to properly service our customers and work efficiently. In these difficult economic times it becomes increasingly difficult to find room in the budget for training employees.

To have our technicians go through a class of the caliber that you provide at no cost is a tremendous boost for our company. Every bit of profit margin we receive from our increased proficiency will be especially important in the current state of our market. We truly appreciate the support.

We are commissioning our first Trio controller, the software it’s great, so easy to use.

Having dealt with the CANOpen state machines on another manufacturer's product, I can honestly say that I am glad that most of the EtherCAT protocol and state machines are handled behind the scenes in the Trio!

Yesterday a customer approved the instalation of our supply in their factory after testing the machine with the MC664-X.

There are 5 EtherCAT axes... We incorpored advanced diagnostics and have full local and remote access to all components over ethernet

We want to thank Trio for the help. Without it we couldn't have completed the job to the level that we wished for.