Development Tools

Overview

Trio has developed a set of powerful softwaredevelopment tools to use with every Motion Coordinator. These tools provide all the features necessary for setup, programming, cam profile generation, robot control and CAD path conversion to ensure a minimum development time.

Some of these add on tools are included in the latest release of Motion Perfect.

All of our programming and utility software is FREE with no support charges or licence fees.

CAD2Motion

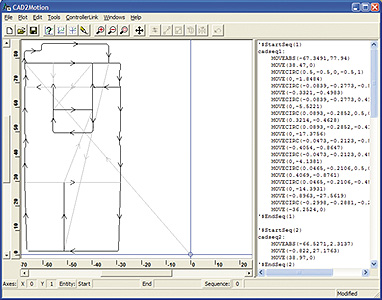

CAD2Motion is a program designed to allow users to translate CAD generated two dimensional motion paths into the Trio Programming Language programs.

The program allows the user to create motion paths in a CAD package such as AutoCAD and convert them into code executable by a Trio Motion Coordinator. Typically the path information will be drawn on a single layer in the CAD package and exported as a DXF file. The DXF file (layer with motion path only) is read into CAD2Motion to create a program to follow the motion path.

The motion path can be manipulated and edited before being saved as a Trio Programming Language file which can be loaded on to a Trio Motion Coordinator.

Benefits

- Can read Industry standard DXF files and Trio Programming Language files.

- Outputs files as TrioBASIC programs.

- Graphical display of motion path with full pan and zoom facilities.

- Built in program text editor.

- Program list and graphical display linked together to show correlation between program code and moves within the motion path.

- Built in tools to mirror, scale, shift, reverse and rotate motion paths.

- Full undo on all tool and editor operations.

| File: | CAD2Motion_1_2_5_Setup.zip |

| Version: | 1.2.5 |

| Size: | 2187491 bytes |

| Date: | 2016-Dec-13 |

This software is FREE.

Compatible with:

MC4, MC5, MC6xx range, Euro4xx range, MC302X , MC302-k, MC224, MC206(X), PCI208, Euro209, Euro205(x), MC202, MC2

CamGen

(Included in MPv4)

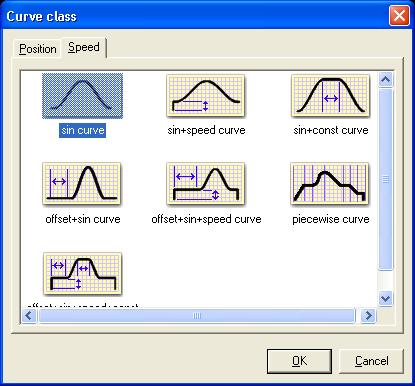

CamGen is easy to use. The most common shapes are included for the user. All you have to do is enter your dimensions and the program will build the cam profiles. Alternatively you can build shapes from tables of points and flexibly specify the shape in-between using curves and straight sections

CamGen is so simple to use, you can import a set of points from Excel and build a smooth motion profile in a few minutes.

CamGen exports TABLE statements ready to paste into a Motion Coordinator BASIC program. Or you can have more flexibility by using CamGen to write a BASIC routine, which will build the cam shapes while your machine is running. CamGen even constructs example CAM and CAMBOX statements to put into your program.

Benefits

- Easy specification of motion profiles commonly used in machinery

- Outputs files as Trio Programming Language programs or TABLE points

- Graphical display of motion position/speed/acceleration curves

- Build piecewise curves with straight, polynomial and spline sections

- Generates example CAM/CAMBOX move statements

- Import sets of points from Excel

- Will handle multiple sector CAM shapes

| File: | CamGen_1_0_7_2_Setup.msi |

| Version: | 1.0.7.2 |

| Size: | 1884160 bytes |

| Date: | 2013-Sep-03 |

This software is FREE.

Compatible with:

MC4, MC5, MC6xx range, Euro4xx range, MC302X , MC302-k, MC224, MC206(X), PCI208, Euro209, Euro205(x), MC202, MC2

For MC4, MC5 and MC6 ranges, use the Cam Library feature in Motion Perfect version 4.

AutoLoader

A compact, self-contained package designed to allow simple distribution of projects written using Motion Perfect. Simply add the project to the Autoloader folder, edit a script file to provide control of the loading sequence and send to the customer.

The Autoloader, complete with project files is small enough to distribute efficiently via email and the end user needs only minimal PC knowledge to complete the loading process.

| File: | AutoLoader_1_7_2_4041.zip |

| Version: | 1.7.2.4041 |

| Size: | 1053715 bytes |

| Date: | 2019-Sep-13 |

This software is FREE.

Compatible with:

MC4, MC5, MC6xx range, Euro4xx range, MC302X , MC302-k, MC224, MC206(X), PCI208, Euro209, Euro205(x), MC202, MC2

MCLoader

MCLoader is an ActiveX component that can be added to a Windows PC application written within Visual Studio or with similar programming tools.

The methods included in this ActiveX allow the user’s PC application to load complete projects or individual programs into the Motion Coordinator. If appropriate then one or more programs can be set to autorun on power up. Functionality also includes check controller type, check firmware version, load TABLE data, display progress bar and many more. The installation includes a Windows Help file with details of each method/function.

| File: | MCLoader_1_7_2_Setup.zip |

| Version: | 1.7.2 |

| Size: | 1342124 bytes |

| Date: | 2019-Sep-13 |

This software is FREE.

Compatible with:

MC4, MC5, MC6xx range, Euro4xx range, MC302X , MC302-k, MC224, MC206(X), PCI208, Euro209, Euro205(x), MC202, MC2

TextFileLoader

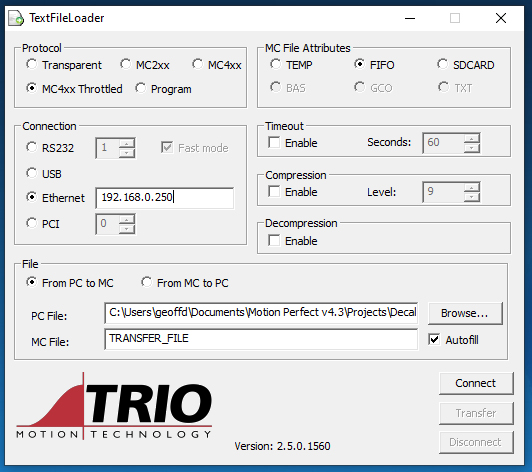

The file loading functionality of the Motion Coordinators allows files to be easily loaded into the controller memory or the SD card (when fitted). This allows programs written in text based languages such as G-Code and HPGL to be loaded to the controller where they can be parsed and executed by a Trio Programming Language program.

The transfer process is optimized to compress the file and reduce transfer times, or it can be set to stream the file into a FIFO buffer on the controller. This can help reduce overall machine cycle times when file sizes can be large and so making communication time significant.

To send the files to the controller, the TextFileLoader standalone application can be downloaded (see box on the left) and used as a readymade application.

The file loading functionality is also built into PCMotion so customised interfaces can be developed. There is an example Visual Basic 2010 project available which can be used as a template or imported into any user application. Application Note .

Application Visual Basic file (zipped)

A "Pickup and Learn" guide introducing the fundementals of the TextFileLoader is available here.

| File: | TextFileLoader_2_5_0_Setup.msi |

| Version: | 2.5.0 |

| Size: | 1875968 bytes |

| Date: | 2020-Feb-28 |

This software is FREE.

Compatible with:

MC4, MC5, MC6xx range, Euro4xx range

G-Code

The Trio Series 4 and above Motion Coordinators have the ability to save and read text files, operate FIFO buffer files and receive text data such as G-Code and HPGL. This new text file handling allows the BASIC to process either pre-recorded G-Code files or to stream G-Code information coming in real-time to a serial port or the Ethernet port.

Example G-Code dispatcher programs can be made available, which can then be used as the basis for a machine development. The examples cover the use of F, G, M, S and T codes controlling up to 3 axes. However, this can be easily extended to respond to other G-Codes as required and to run more than 3 axes. Besides the dispatcher, a G-Code parser is required. This, and the dispatcher, is written in BASIC so is fully adaptable by the machine builder or system programmer. Trio’s engineers can work with the customer’s software developers to help complete the G-Code project to the customer’s requirement. Please contact your Trio Distributor for details.

The Trio Motion Coordinator is not a CNC controller in the true sense. It is not a simple drop-in replacement for a full function CNC provided by companies who offer turn-key solutions in this field. However, the flexibility of the Trio software makes it ideal for designing specialized machines which use G-Code as the motion command source. Our customers have, for example, made multi-axis wood working machines which use G-Code, taking codes from a CAD-CAM system to produce machined products for specialized markets.

Trio Drivers

Installer patch... (For use with Autoloader if Motion Perfect is NOT installed)

The patch includes USB drivers that can be installed in Windows 95, Windows XP and some PCs using Windows 7. The drivers have not been updated to be fully compatible with later Windows versions and is not fully compatible with all USB hardware on modern PCs. The patch is provided for support of older legacy systems linked to the MC2xx range Motion Coordinators.

This software is FREE.

Unified API

Trio's Unified API is set of libraries allowing direct connection to the Trio Motion Coordinator from a PC based user application. Supporting Windows and Linux the Unified API can be used to develop motion applications based on Trio's powerful Motion-iX command set.

The Unified API supports either TCP/IP connection to the Motion Coordinator, or the shared memory interface for PC-MCAT-2 and Flex-7. The aligned command sets allow the PC applications to target different platforms with a change to only one line.

Trio's Unified API can be used with any programming environment that supports Dynamic Linked Libraries (DLL).

Downloads are available for Windows and Linux.

Benefits

- Libraries supporting Windows or Linux

- NuGet package for .NET development

- Python package available for Windows and Linux

- 32-bit and 64-bit Libraries

- Common syntax across all platforms

- Exception Based Error Handling

- Access to Motion-iX command set:

• Reading and writing to axis and system parameters

• Reading and writing to controller variables (TABLE and VR)

• Running motion commands

• Loading files to the controller via TCP/IP only

Windows

| File: | Trio_UnifiedApi_1.2.0.msi |

| Size: | 41934848 bytes |

| Date: | 2025-Sep-25 |

Linux

| File: | Trio_UnifiedApi_1.2.0.tgz |

| Size: | 15205349 bytes |

| Date: | 2025-Sep-25 |

This software is FREE.

Software Release Notes (log in)| Application Notes |

|---|

| Unified API Application Notes in C, C++ and C# |