Applications

Trio products can be found in virtually every industry around the world.

| Pipe Bending | |

|---|---|

The production of curved, profiled stainless steel clamp components to aircraft standards has undergone a revolution with the introduction of a new machine from Kidderminster Engineering Services (KES) Eaton Aerospace selected KES to develop an improved process for the production of a range of clamp components, seeking lower production costs, higher throughput and a substantial reduction in turn-around times between different types of component. Employing a Trio Motion Coordinator, the new machine was developed jointly by Eaton, KES and software specialist LMS ServoTechnics. The ring roller features quickly-replaceable profiling roller assemblies, through which the steel strip is passed before reaching the innovative bending and cut-off unit. The results are "U" or "V" shaped components curved and cut to length to very high standards of accuracy. Benefits

|

|

| Six Axis Hexapod | |

|---|---|

Hardware

Gapp were invited by Absolute Moco to control the position loop for a hydraulic ram used in various film sequences. In normal operation, the ram was opening and closing at full speed with no control. Gapp proposed a Trio MC508 with SSI encoder feedback from a Siko wire pull encoder. The customer replaced the standard hydraulic valve for a proportional valve that could be controlled via a +/- 10V analogue output signal. Once the position loop had been implemented, the SFX team requested some help with the second phase of the project. They had to build a six axes hexapod with hydraulic rams. To control the rig, they required a GIMBAL to be able to teach the system the movements required and to be able to edit and play back the sequence. Since the original development for the film ‘LIFE’ the software and hardware has been further developed by the SFX team and the solution has been used in other film projects. Gapp has been involved with the additional developments for each movie. Gapp continues to be part of the SFX development using Trio Motion Coordinators. Thank you to Absolute Moco for permission to use the video clip. |

|

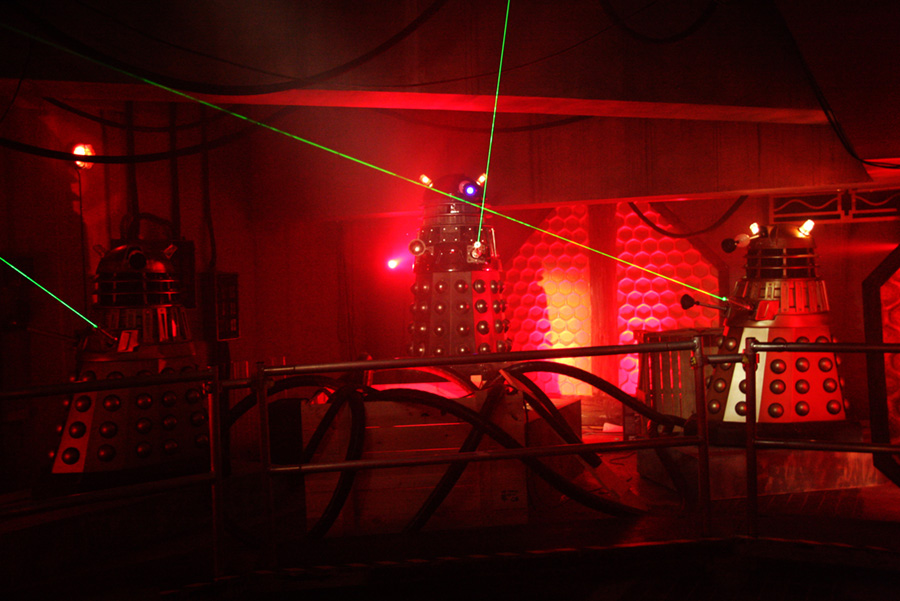

| Exterminate! | |

|---|---|

Hardware

Animating the Daleks! London based Windmill Studios provide audio-visual solutions for the conference, live events and attractions industry and when Trio Motion launched a special offer for evaluation kits, it seemed an ideal opportunity to try out the Motion Coordinator whilst saving costs for a special effects project that involved animating Daleks in a visual panorama of synchronised graphics and motion for the phenomenally popular Dr Who Up-Close Exhibitions. The MC206X controlled each Dalek’s floor movement via a two-axis servo motor driven carriage and with its own on-board digital I/O and an additional 16 channel CANbus I/O module, also sequenced the start-stop positioning of several brushed DC motor driven axes for the rotating and vertically actuated head, the Dalek’s famous ‘gunstick’ and manipulator arms, as well as handling a variety of synchronised lighting and mechatronic effects. |

|

| Television on a stick | |

|---|---|

|

Hardware

Filming at altitude Trio Motion Technology’s Motion Coordinator is being used to provide position and stability control for a 30 metre camera mast that provides sweeping high-angle aerial shots for film and TV. The Vortex Aerial Mount Camera System, developed by professional cameraman Matthew Gladstone of Cammotion with the help of automation specialist Machinery Control Systems (MCS), is completely portable and can be rigged and de-rigged in minutes - making it suitable for a wide range of spectacular shots for outside broadcast and film studio work. Vortex is controlled by an assistant, working under the cameraman’s direction, using a hand-held pendant with joysticks for progressive control of all movements. It also incorporates a number of load cells for measuring critical forces on the structure. Consequently, the Trio MC206X Motion Coordinator has to handle a wide range of analogue and digital signals. The different functions are interlocked in logic, to ensure safe operation at all times. |

|

| Autonomous Disinfection Robot System | |

|---|---|

Hardware

Benefits

|

|

| Carton Folding | |

|---|---|

|

JD Innovation specialises in retrofitting carton-folding machines. A Motion Coordinator controls a servo motor connected to a hook. The carton position is recorded using the fast-registration input on a separate incremental encoder input. The system uses the CAMBOX motion command to position the hook relative to the incremental encoder. For up to 2 hooks the system is designed with one Motion Coordinator as shown in the picture. The Motion Coordinator is equipped with an Ethernet Daughterboard for communication with a Pro-Face touch screen. For machines with more than 2 hooks the same Ethernet network allows the Motion Coordinator to communicate. |

|

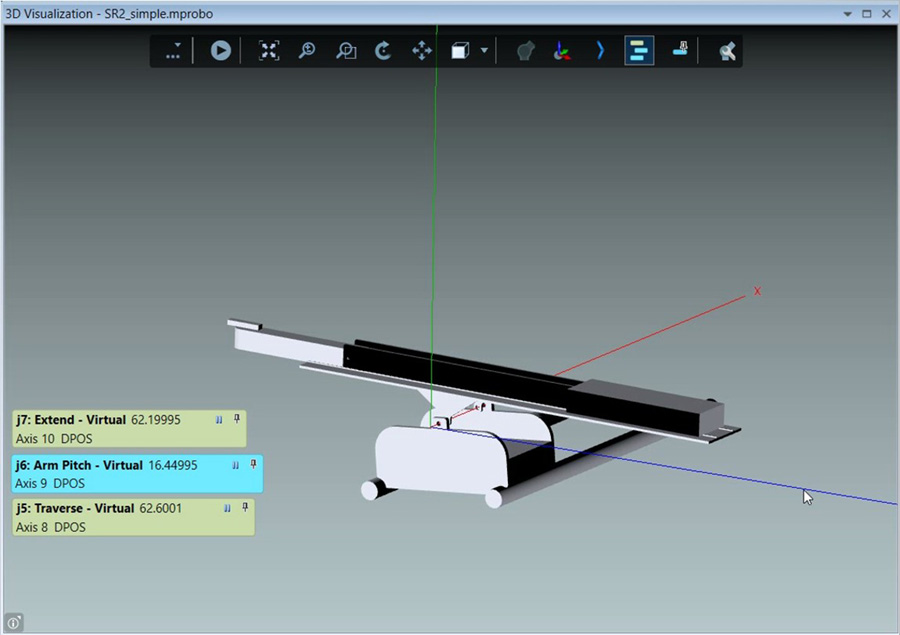

| Three Axis Robot | |

|---|---|

Hardware

This three linear axis delta robot was specifically developed for a particular customer that needed to speed up the process of sandwich making. The robot is designed to work in clean areas at low temperature without compromising the production process. The customer required a solution not only to control the robot, but also the conveyor and near working area where sensors monitor the environment for any eternal hazards. All this was achieved in an easy programming environment: Motion Perfect. Benefits

|

|

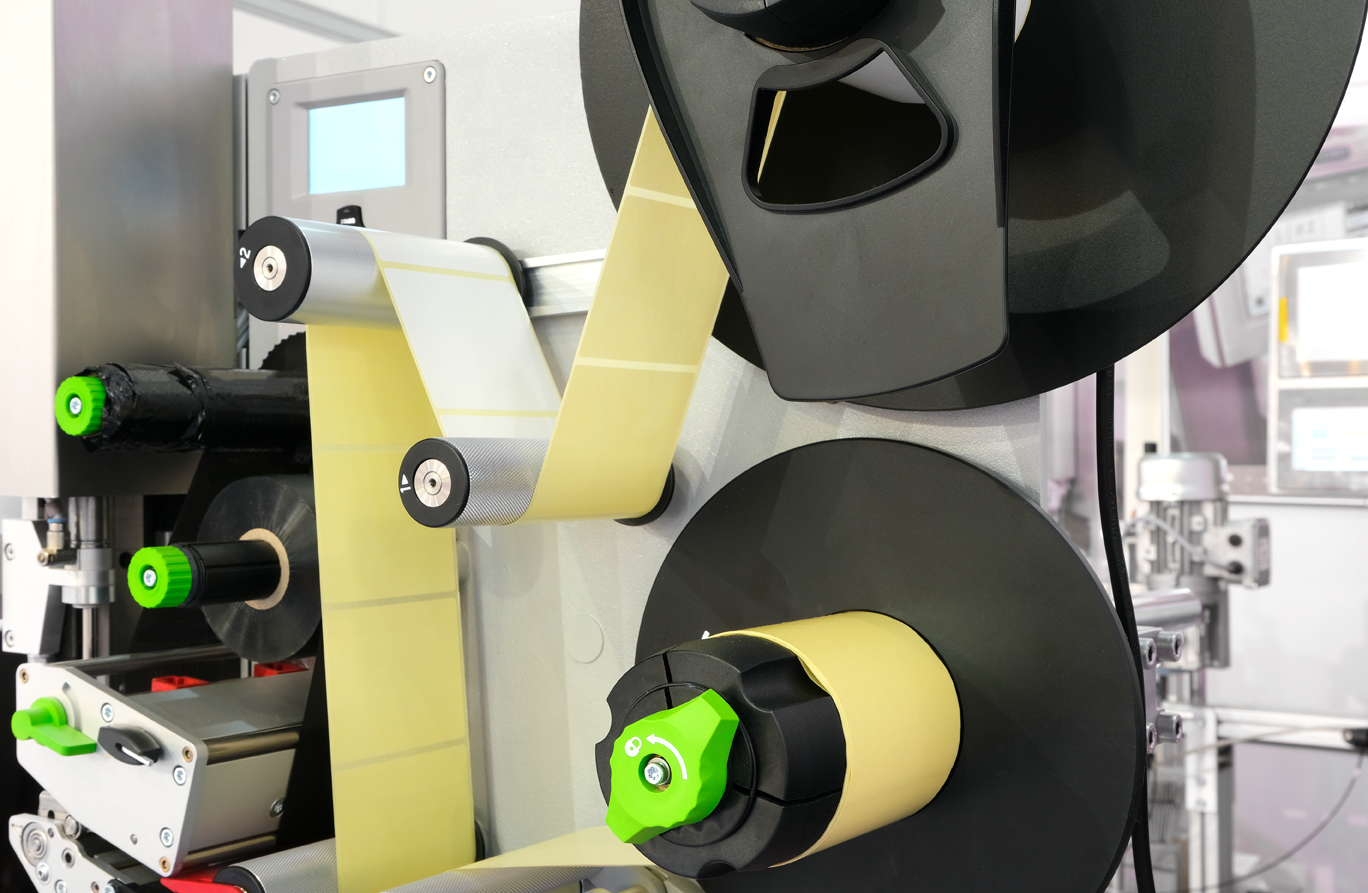

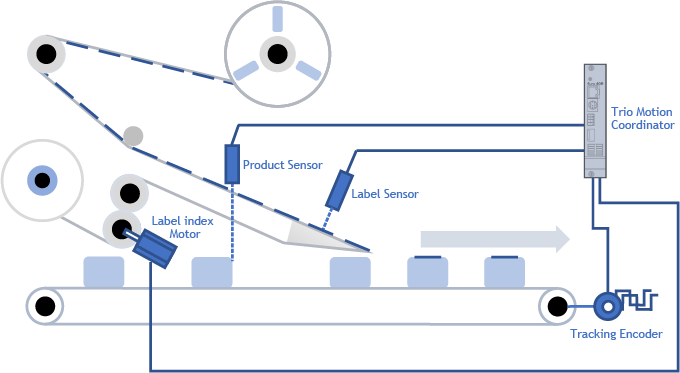

| Accuracy and throughput of labelling machines increase with Trio |

|---|

A large labelling machine OEM in the USA has upgraded the motion controllers on its machines to boost throughput and increase label application accuracy. The labelling machine builder has integrated controllers from motion control specialist, Trio Motion Technology, to increase throughput by over 25% with labelling accuracy improving to +/- 0.5mm, as well as create a future-proof design. Requiring precision and speedFounded over 100 years ago, the OEM designs and builds hundreds of machines every year for packaging and labelling applications, primarily in the food & beverage market as well as the medical and pharmaceutical industries. In addition to packaging meat, poultry and seafood, the packs have to be labeled, placed with a high degree of accuracy that is repeatable over thousands of units. High volume production also means that high speed is required to maximize throughput. The machines can include both top labeling for branding and bottom labeling displaying product data such as nutritional information. Added directly after the packaging machine, the inline labelers form part of the production process and must coordinate with the speed of the infeed conveyor, which can vary based on multiple factors including conveyor loading, mechanics, and voltage fluctuations to the driving motor. The next challenge is for the labelling machine to accurately apply the labels, maintaining accuracy even when infeed of packs is high. Previously, the labeling machine OEM used a programmable HMI to provide control. However, greater accuracy in label placement was required by the OEM’s customers which decreased with variation in conveyor speed. Trio’s solution

The labelling machine OEM turned to experienced motion control manufacturer, Trio Motion Technology, to provide a solution that improved accuracy which would not deviate at high throughput. The controller also had to provide easy integration as well as increased reliability to maintain productivity. Trio’s Euro404 Motion Coordinator was selected to control two stepper motors and accept a line encoder for precise conveyor tracking. The Euro404 accurately registers and feeds the top and bottom labels to the incoming packs. Equipped with precise 64-bit motion calculations on an ARM11 Processor and floating point math, Trio’s Euro404 controller has increased accuracy in label placement by 50%, from +/-1.0mm to +/- 0.5mm. Crucially, the Trio controller maintains high accuracy repeatability irrespective of the speed of the conveyor and product inflow, meaning that throughput can be increased. This is achieved with standard features in the controller for registration capture-to-motion triggering and electronic gearing. The gearing feature tracks the speed of the conveyor via encoder input and precisely synchronizes the label feed motion. Total throughput depends on the size of the pack, but the machine is now capable of placing up to three labels per second, or 180 labels per minute. This has increased machine throughput by over 25%. The previous system was unable to track the speed of the conveyor and the incoming packs in real time, resulting in the throughput versus accuracy tradeoff. Trio’s Euro404 controller is provided ready to mount onto a control board, in this case manufactured by the labelling machine OEM, that interfaces directly to the controller. The Euro404 required no modifications, enabling faster time to market and reduced cost. It was also a requirement of the control board to have a compact footprint to minimize the overall size of the machine. The controller fits into a low-profile board and enclosure, helping to achieve the low floorspace requirement. The original smart HMI also presented a program compatibility challenge depending on the model required for the various labeling machines in the OEM’s range and it didn’t have an upgrade path for obsolescence. Instead, Trio’s controllers use the same program with no reprogramming required, and the Euro range has an upgrade path for both stepper or servo control. Trio’s future proof system allows previous generation programs to load and run into the latest generation controllers. Time and cost savingsThe Euro404 is also very easy to use. Interfacing with a control panel and e-stop, all settings are managed through a compact touch screen. Flexible control is provided though the user only needs to set the label size along with a calibration run in order for accurate, high throughput operation to start. As Trio’s environment for motion and machine control is a single integrated system, it’s easier to work with and doesn’t require an HMI or PLC to coordinate and control additional devices required for label registration. A more stable programming system compared to the previous smart HMI approach is also combined with more reliable hardware in a robust package and a single unit, reducing the volume of required connections. For the OEM this has significantly reduced downtime contributing to more productive machines. Combined with increased accuracy and throughput, Trio’s controller has also helped to reduce cost, with fewer maintenance requirements, less development time required, and better value hardware compared to PLC or HMI options. The OEM manufactures around 150 labeling machines per year, meaning that significant cost savings are achieved. Trio also provides controllers for stepper, servo and Ethercat labelling applications that can scale to more demanding and complex labelling systems. |

| Liquid filling machines increase productivity with motion control solution |

|---|

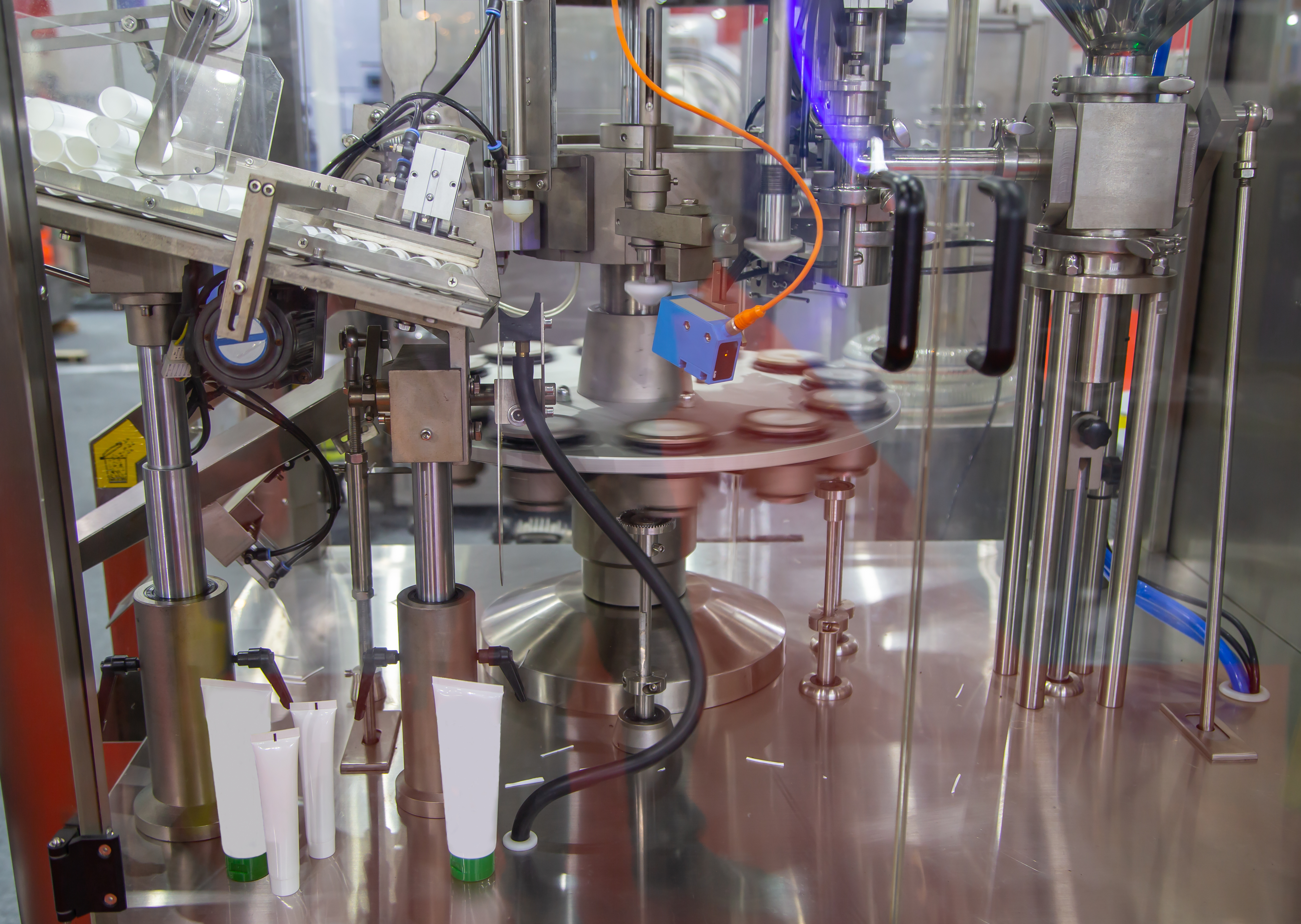

A liquid filling machine builder has increased machine speed by 8% and boosted machine efficiency to 91% after upgrading from a PLC system to a motion control solution. Liquid filling sachet and tube packaging solutions provider, Unette, has integrated Trio Motion Technology’s complete machine control package including controller, servo drives and motors, to improve its overall productivity. The upgrade has also increased reliability that has reduced downtime, as well enabling a faster machine set-up. Founded in 1962, Unette builds and operates bespoke machinery for a form, fill and seal process unique within the packaging industry. Covering all types of liquid filling including toiletries, nutraceuticals and medicines, Unette’s customers include global household brands who choose Unette for the speed and quality of service and professionalism. Based in Cheshire, UK with a team in excess of 50, the plant has capacity for 1.85 million dosing cycles per week. The group also has a facility in New Jersey, USA, with a further 250 staff. The challengeHistorically using cam-operated machines, Unette began to combine motion control with servo and stepper motors to improve speed and accuracy. With its two-axis filling and printing machine, tubes are formed individually before cyclically filled with product. They are then die cut shaped, multi coded and any appendages attached. The cam indexer moves the rotating carousel that holds the tubes until the plate is in the correct position. At that stage, one servo axis controls the motion of the filling heads that dispense the media, the other controls movement of the film for applying brand and product information on the tubes. These two actions have to be synchronized to the main cam and must be coordinated at precisely the right time to ensure accuracy of filling and over printing. This process also has to be implemented at high speed in order to meet demanding productivity rates. Previously, Unette used a PLC with a servo package from multiple vendors to achieve the motion control. However, to improve productivity, the accuracy of fill and print registration needed to be increased, as well as the speed of control. Accumulated errors also decreased reliability and using different vendors for the various components within the system resulted in a lack of compatibility. “Allowing the PLC to coordinate the motion created problems in accuracy and reliability. We wanted a stable approach with more productivity,” says Martyn Hudson, Founder and Chief Engineer, Unette. “Not only was the level of control not achievable with a PLC, we couldn’t get the PLC and the servo drives to talk to each other reliably at speed and neither vendor could resolve the issues,” adds Martyn. “We wanted a simpler approach. Using a motion controller has not only proved to be more effective, it has also saved us money and made changes easier by less skilled staff.” Increased productivity

Trio installed a complete machine solution, including its highly compact Flex-6 Nano motion coordinator with dual core processor, combined with two Trio DX4 servo drives and Trio MX series servo motors. The Flex-6 Nano controls the entire process, including packaging and filling, from infeed to outfeed. Efficiency has increased through Trio’s fully integrated motion control solution that has reduced downtime, improving productivity as a result. Not only has machine speed increased by 8%, daily efficiency of the machine has risen to 91% and Unette is confident that this figure can be further improved. Trio’s coordinator has not only enhanced the machine’s motion control, but it can also command the required logic functions. “The Trio motion coordinator now manages the areas of process control formerly taken care of by the PLC,” says Martyn. “This means that the motion coordinator can also control the timers and counters, for example managing shift registers for the in-line process control to make sure we don’t have any faulty packs coming out of the finished delivery chute, which would otherwise involve more downtime or reduce batch quality.” Fast, simple set-up

The machine’s original motion control commands have been replicated by Trio’s motion coordinator, combined with replication of all PLC controls which were added via IEC 61131-3 programming. Set up of the controller and drives takes place within Trio’s Motion Perfect software, and with no special programming required, the application runs on the Trio controller’s standard functions. For Unette, it was an advantage that the Trio system is managed by a single software programme. “The software achieves what we were previously attempting with several individual platforms. As the software interconnects the controller and servo, it’s more user-friendly and will hopefully save us a lot of time and cost in installation and commissioning future machines.” Trio’s interconnected machine solution reduces the requirement for hard wiring as no cross-addressing is necessary between equipment from different vendors. In terms of programming, the new solution provides a considerable saving for Unette, which typically reprogrammes its machines every few days depending on the requirement of its customers. “In future, there’ll be less and less need to develop new code. This will save us a lot of time and enable faster development for each new application,” says Martyn. Easy integrationIn addition to rapid commissioning, physically the Trio hardware integrates easily into Unette’s existing machine. The pocket-sized Flex-6 Nano is just 147 mm in height and is the width of an I/O slice, while the servo drives are among the most compact for their rating. Trio’s products are also backwards compatible with support ongoing for 20 years-plus, and this remains the case for many of Trio’s early controllers that are still in service. This is a crucial area for Unette. “We over engineer machines to keep them flexible and for use in the field for a long time, so we need a guarantee of support and compatibility for legacy products, including backwards compatibility,” says Martyn. “For example, we’ve just taken a machine offline after being installed in 1966, so we need long-term support.” Future developmentWith over 20 machines in total, Unette now has three machines operating with a full Trio solution and the company will begin to migrate its other machines to Trio. Unette will also implement additional controls such as pick-and-place for inserts into flexible packaging. While Unette is confident of long-term efficiency gains in man-hours and reliability, a saving has already been made at outset with the company reporting that the package is around 8% more economical than other vendors. |

| Mask Making Machine | |

|---|---|

|

Hardware

Virus Protection With the world-wide spread of the Coronovirus, masks are used as a protective barrier to prevent cross-contamination among crowds. They are made mostly from non-woven fabric and are available in the two-layer or three-layer form. The inevitable use of facemasks is expected to propel the global facemasks market during the forecast period. The layers are ultrasonically welded for efficient bacterial filtration. Bacterial filtration efficiency(BFE) is the effectiveness of the surgical mask material to filter bacteria of a specified particle size. Particle filtration efficiency (PFE) is the effectiveness of a material to filter aerosol particles. Both BFE and PFE are expressed as a percentage of a quantity that does not pass through the material of the masks. Benefits

|

|

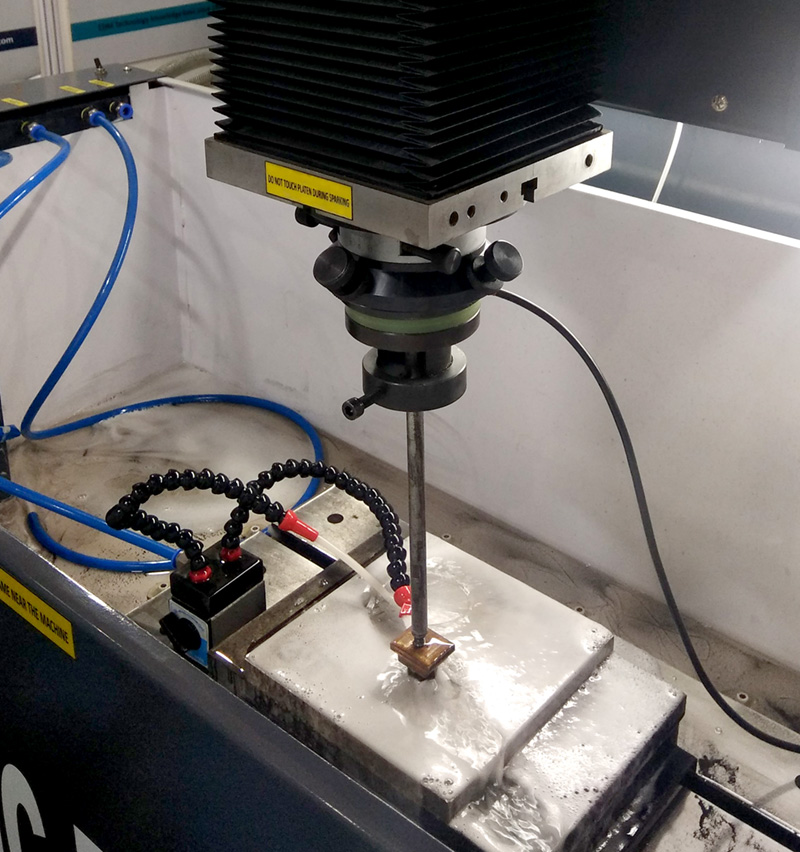

| CNC EDM | |

|---|---|

Hardware

Benefits

|

|

| Wire EDM | |

|---|---|

Hardware

Benefits

|

|

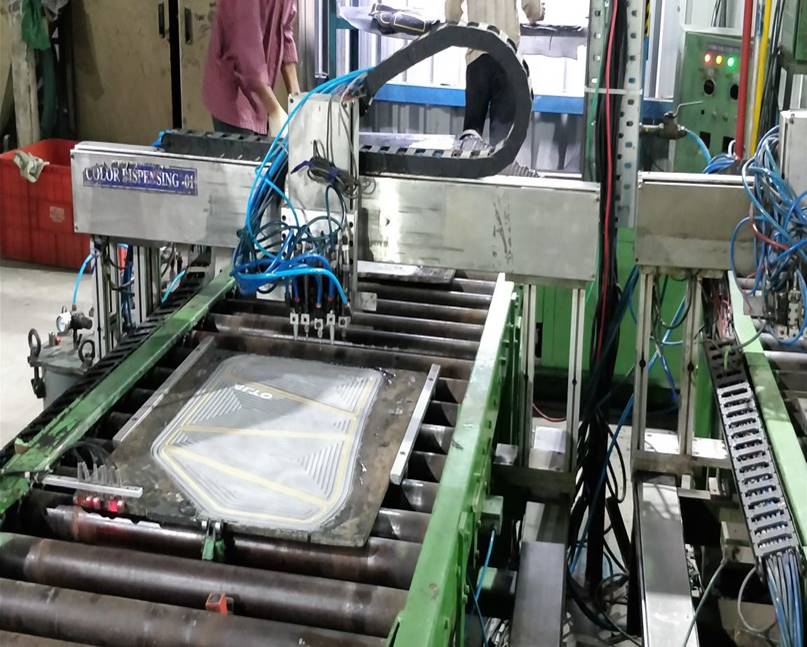

| Glue Despensing Machine | |

|---|---|

Hardware

Benefits

|

|

| labelling machines | |

|---|---|

Feeling the Pressure Harland’s labelling machines find applications in many industries, with customers ranging from small local suppliers to blue-chip internationals. The diverse needs of this global customer base are met by the adoption of a modular approach which employs a number of standard systems modified as necessary to suit the precise requirements of each application. The application of pressure-sensitive labels requires very high precision of initial placement, accurate control of the pressure system which bonds the label to the container, and effective product handling. Even the smallest and simplest of Harland machines is still a remarkably complex engineering achievement. Such machines are expected to perform reliably for many years with minimal maintenance, requiring very high standards of design and build quality. |

|

| Vertical Packaging Machine | |

|---|---|

|

Hardware

Estun's Vertical packaging machine is a common packaging machine. It’s suitable for packing all kinds of powder, particles, tablets and other materials Material feeding, plastic film through the film cylinder to form a cylindrical shape, through the heat sealing roller longitudinal seam side, cross cut sealed bottom. The package is put into the bag and sealed horizontally |

|

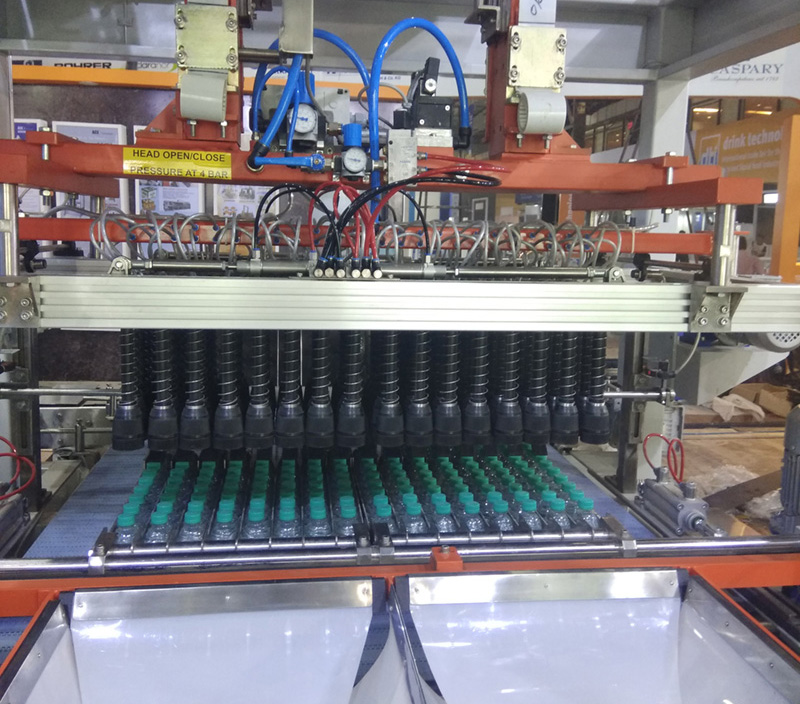

| Low Pressure Bottling Plant | |

|---|---|

Hardware

Benefits

|

|

| Robax Packager | |

|---|---|

Hardware

The Robax Packaging machine an automatic pick and place system on XY motion with single belt configuration. This picks up 45 - 95 bottles at a time that are placed in crates or corrugated cartons for further packing. Benefits

|

|

| Sleeve Application and orientation of Bottles | |

|---|---|

Hardware

Benefits

|

|

| Metal Box Packing | |

|---|---|

Hardware

Benefits

|

|

| Carton Folding | |

|---|---|

|

JD Innovation specialises in retrofitting carton-folding machines. A Motion Coordinator controls a servo motor connected to a hook. The carton position is recorded using the fast-registration input on a separate incremental encoder input. The system uses the CAMBOX motion command to position the hook relative to the incremental encoder. For up to 2 hooks the system is designed with one Motion Coordinator as shown in the picture. The Motion Coordinator is equipped with an Ethernet Daughterboard for communication with a Pro-Face touch screen. For machines with more than 2 hooks the same Ethernet network allows the Motion Coordinator to communicate. |

|

| Paper Cup 4 colour Flexo Printing & Punching Machine | |

|---|---|

Hardware

Benefits

|

|

| 5 Axis Articulated Industrial Robot | |

|---|---|

Hardware

Benefits

|

|

| Three Axis Robot | |

|---|---|

Hardware

This three linear axis delta robot was specifically developed for a particular customer that needed to speed up the process of sandwich making. The robot is designed to work in clean areas at low temperature without compromising the production process. The customer required a solution not only to control the robot, but also the conveyor and near working area where sensors monitor the environment for any eternal hazards. All this was achieved in an easy programming environment: Motion Perfect. Benefits

|

|

-The Motion Specialist-

- UL Ref: E238097

- ISO 9001:2019

- © Trio Motion 2025