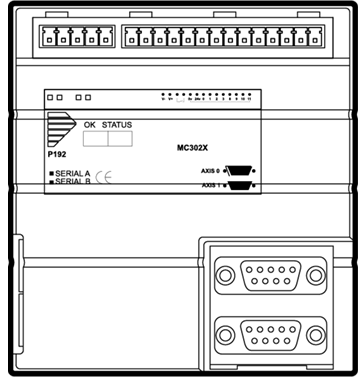

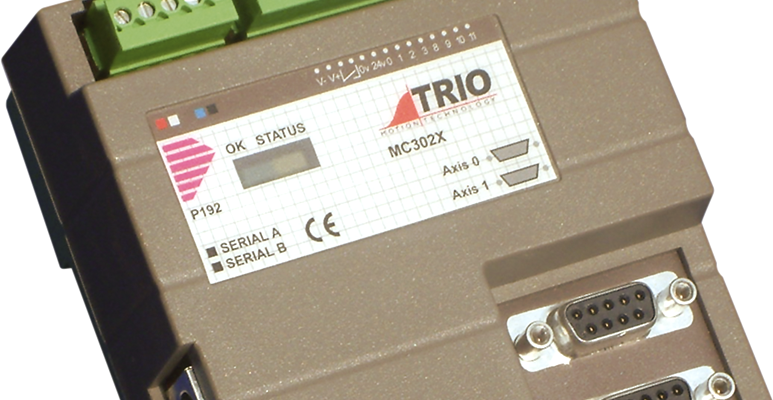

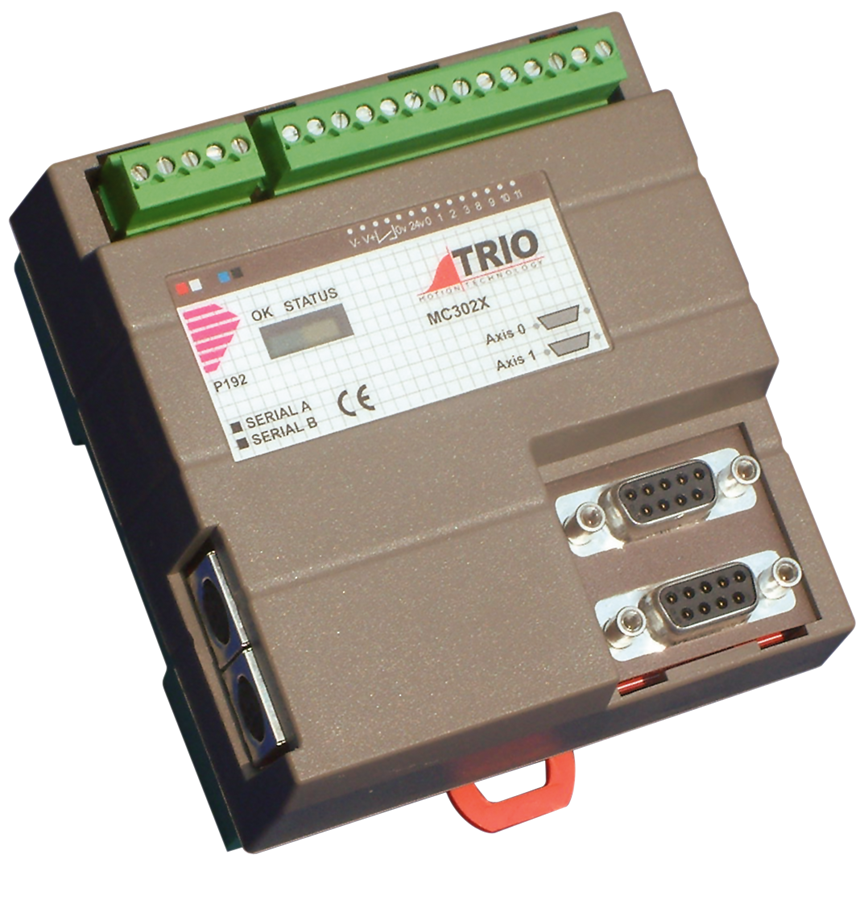

The Trio MC302X is a DIN rail mounted motion controller based on ARM processor technology.

Highlights

- Compact 94w x 48d x 101h

- Easy DIN rail mounting

- Multi-tasking TrioBASIC system, maximum 3 tasks

- Motion Perfect Application Development Software

- CAN Networking

- Watchdog Status LEDs

- UL and CE Approved

Ideal For:

It has been designed to provide a compact, cost effective solution for OEM applications. The unit features two axes, the first of which can be configured in software for either servo (with encoder feedback) or stepper control. The second axis may be either a reference encoder or a stepper axis. The differential line driver stepper outputs can be configured for simulated quadrature encoder outputs to synchronize multiple units. The built-in registration facilities make the MC302X ideal for Flying Shears, Winders, and highs peed Labelers.

Flexible

Each axis may run moves using linear or circular interpolation, electronic cams and gearboxes. Support is provided for continuously rotating machinery and two of the inputs may be configured for accurate hardware registration.

The MC302X has (4) 24V inputs and (4) bi-directional input/output channels built-in. These may be used for system interaction or may be defined to be used by the controller for high speed registration, end of travel limits, datuming and feedhold functions if required.

Communication

The MC302X can have up to 256 external Input/Output channels and up to 32 analogue input channels, connected using DIN rail mounted I/O modules, via the on board CAN channel of the MC302X. The MC302X has an RS232 programming port, and a user selectable RS-232/485 port